The process of metal treatment is essential on a frequent and sustainable outdoor use equipment. FitPark® pays particular attention in its workshops to respecting each of the processing steps.

Thermoplastic : Ideal treatment for harsh environments

High-performance thermoplastic coating is known for its exceptional durability and corrosion resistance. Extensive laboratory testing and real-world use indicate a lifespan of decades.

It is an ideal solution for protecting metals in the most demanding environments, whether for urban applications, sandy or by the sea. Its durability, Excellent abrasion resistance and environmental friendliness (free of harmful substances such as BPA, VOCs, phthalates or heavy metals) en font un choix privilégié pour les professionnels.

Polyester primer

The anticorrosion primer is applied by dusting using the classic material of application of powder paints. Les primaires anticorrosion bénéficient des commodités d’application des peintures en poudre et présentent une technique avantageuse avec notamment des coûts de mise en œuvre réduits par rapport à un revêtement thermoplastique.

Grenaillage and thermolaquage

When gridging, The high-speed projection of metal particles allows the surfaces of parts of all fats and calamines to be stripped clear and to create a roughness allowing a better grip of the treatment. Metal shot is used more than once, Thanks to a circuit of automatic cleaning.

Follows the thermolacing operation. The metal parts are powdered polyester paint, then baked. Cooking polymerize paint powder, donnant à la pièce traitée une épaisseur de protection supplémentaire ainsi qu’un aspect parfaitement fini lisse brillant ou texturé mat.

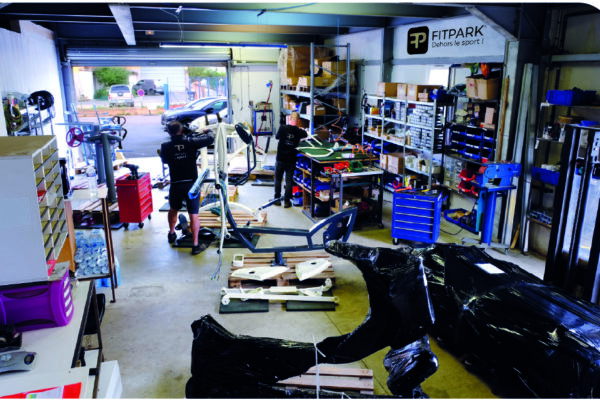

Assembly

For the reliability of the equipment, assembly is an essential step. This phase is carried out in our workshop, by our care, in order to bring maximum finishing quality.